Piston Engines of the New Generation (Without turbo – supercharging)

000

ОтложитьЧитал

Editor Фарида Бинятулловна Мирзамова

Translator Анастасия Сергеевна Агафонова

© Anatoly Matveevich Druzhinin, 2018

© Анастасия Сергеевна Агафонова, translation, 2018

ISBN 978-5-4493-6090-8

Created with Ridero smart publishing system

The book gives an analysis of mistakes in the generally accepted calculations of piston rings, carried out without taking into account the influence of physical laws on the operation of rings (gas dynamics, hydraulics and thermodynamics). Based on the analysis, the formula of determining the piston ring height was initially obtained. Essentially new designs of “piston devices” have been developed, in which the sealing and oil-removal piston rings are located in one piston bore located at the top of the piston. Integral construction of the piston device increases the efficiency of the engine, its power and life, reduces fuel and engine oil consumption, improves the environmental characteristics of the engine and eliminates the need for turbocharging.

The book presents updated and revised information on previous editions, adapted to the features of powerful and heavy-duty engines and compressors. The temperature changes in the shape and dimensions of the cylinder, a new piston rings combined into one contraction reduce to a minimum mechanical friction losses, to increase the engine power and resource, to reduce fuel consumption, to increase oil replacement terms, to improve ecological indicators of the engines. The design excludes application of a turbo-supercharging. The modernization concerns the cylinder-piston group of the engines or compressors, and it does not require fundamental changes in technological processes. The conditions have been created for the use of water in engine processes, and the increased competitive advantages of two-stroke engines was justified.

The book will be useful for the engineering and technical workers of motor-building enterprises, for scientists and specialists on piston devices, for students in higher and secondary educational establishments, for students of faculties and Institutes of advanced training, for driving schools when studying the design of the engines.

About the author

Anatoly Druzhinin Matveyevich, born in 1935, Candidate of Technical Sciences, Associate Professor of the Kazan Scientific Technical University named after A. N. Tupolev. Professional technologist for aviation, rocket engines and internal combustion engines. The problem of increasing the internal combustion engine efficiency has been exploring for more than 30 years, the first invention: Piston seal for ICE, Authors’ certificate, SU, No. 1388572, received in 1986. Inventions: Cylinder piston group of internal combustion engines, patents No. 2624376, 2017 and No. 2,651,694,2018 include all the innovations developed by the author. Totally there are 36 inventions and 6 patents for utility models.

The results of the research have been published in 8 issues of the scientific and technical journal “Russian Engineering Research”, translated into English and distributed all over the world. Two books have been published: Cylinder-Piston Group of the Engines and Compressors: 100% of Innovative Elements CPG/Anatoly Druzhinin. – [B. M.]: Publishing decisions, 2016. -238 C. and Modernization of the Internal Combustion Engines: Cylinder-piston Group of the New Generation, M.: Infra-Engineering, 2017. -150 C.

Druzhinin was awarded a Certificate “For the Best Innovative Idea” A new piston seals for the internal combustion engines” of the Republican competition “50 Best Innovation Ideas of the Republic of the Tatarstan”, 2006.

The book “How Make the Engine Better. New Piston Rings” is a participant of the Moscow International Book Fair, 2017.

The author

“Theory without practice is dead”

Practice is poor without theory. The harmony of theory and practice is the way to perfection”

Preface

The book presents a new edition of earlier published works of the author. The Russian name of this book is inherited from the article “How Make the Engine Better?” which was published in a very authoritative magazine “Russian Engineering Research”. The magazine is included in the list of approved by VAC RF for the publication of works of applicants of academic degrees [1]. The journal is translated into English, reprinted and distributed worldwide by Allerton Press (USA).

It is necessary that the information must be interesting for theorists and practitioners, specialists of the internal combustion engines, to publish an article in such an authoritative journal. Such grounds were. So the series of articles were published, not only in this journal but also in the profile journal “Automotive Industry”.

The book represents a new revision of another author’s book “Cylinder-piston Group of Engines and Compressors: 100% of the Innovative CPG Elements [3]. The contents of the book complement with new information, on inventions was received, the most significant practical proposals, designs, and justifications for their technological realization was reflected.

As a result of many years of searching for the reasons for the low efficiency of the engine, the specialist technologist found a fundamental error of the designers in the most important part of the design of the internal combustion engine (ICE) in cylinder-piston group (CPG).

This mistake claimed a scientific and technical sensation, because for the first time one of the main evidence of this event was published-the gas dynamics scheme of the piston compression ring. Which was opened a new direction in the design of the CPG elements for piston machines of various sizes and purposes.

The gasdynamic scheme and, based on its analysis, the formula of piston ring height determining, made it possible to supplement with the new data scientific and technical and educational literature devoted to solving problems of increasing the efficiency of the cylinder piston group and the engine itself.

In this publication, the attention of specialists is focused on the behaviour of gas dynamics at different cycles of the engine operating cycle. There is a really perspective to starting to improve the engine, in the designing and production process and in use during scheduled or unscheduled repairs.

More than 10 years passed, but the interest in the scientific community, has not appeared. The magazine articles and the textbooks published by the author remain unused. The mystery that the author had to decide and he had to believe he decided it. All this is described in more detail in the proposed edition.

In recent years, the human attitude towards scientific and technological progress has fundamentally changed. The problem of increasing the efficiency of lCE, the need “make the engine better” may be most revealing.

The author had to face with some problems of which did not help to solve the problem of improving the engine efficiency. Some approve principle changes in design others do not. We’ll try to understand these contradictions.

Start from the beginning of the product creation, with designers. Designers often develop a more complex design, forgetting that “simplicity is the sister of talent” and “the best is the enemy of the good”. In our work there is a concrete example, the “turbo-supercharging” of engines which is actively advertised and universally applied. The inexpediency of using the “supercharging”, the author tried to explain in his work [2].

The State Standards were one of the main causes of the artificial “brake” in the theoretical and practical researches. The author sent an article “Which GOST Standard is Better” in the Russian Standard and in the journal, the “Russian Engineering Research”. The editorial board after a long study, without any explanation, removed the article from the publication. The article has already been announced in the media, it was decided to place it in this book, believing that the reader would understand why the article had not published and including whether to use these Standards.

The manufacturer is the next stage in the creation of ICE. The task of the manufacturer to produce what the designers created. But that’s not quite true. They are not interested in the “simplicity” of the design. They are interested in more difficult technique with the higher cost and with great demand of its products. Maybe they want that the engine resource will be bigger. In fact, the less product’s resource, the greater the number it is planned for release.

There are a large number of people who do not want to increase the engine resource. It is a services and repair shops. Accordingly, these are millions of jobs. For the increase of which the state so insists.

Reduction of fuel and oil consumption does not inspire oil and fuel manufacturers. This all leads to a decrease in the receipts of taxes to the state budget.

In conclusion, it is possible to note that: only for the consumer and, perhaps, for the ecologists are important to have a powerful, highly resource, economical, and ecologically pure engine.

There is a violation of democratic principles, that is, a minority wins, but the whole of humanity is losing.

Nevertheless, science cannot stop, and to some extent it is confirmed by this work.

Introduction

In the world practice of engine building, there are more than a billion units of only automobile engines in operation, a huge number of powerful and super-powerful marine diesel engines, stationary power plants of civil and military use are used.

The fundamental changes in the design of the cylinder piston group engines, presented by the author, will increase their effectiveness, resource and competitiveness. The book presents the results of studies of processes occurring in the engine cylinder, affecting the efficiency of the engine, the criterion of which is usually considered the efficiency of the engine.

It is clear that efficiency, which has now reached even 0.5, with the available scientific and technical achievements, cannot correspond to the energy product of the 21st century. There is a suspicion that not everything in the ICE (internal combustion engine) is good as theorists and practitioners consider. Obviously, there are principal reasons, probably of a subjective nature, that seriously affect the working processes in the cylinder-piston group. The author faced a task: to determine these causes and to try, if possible, to eliminate them. As studies have shown, there have been opportunities like this before and now.

There is no doubt about the urgency of the solving problem. Despite the emerging alternative ways and designs of engines, the dominant replacement of internal combustion engines in the coming decades is not expected, especially in such a huge country as Russia. To increase the efficiency of piston machines is not only a technical and economic task, but no less, and for large megacities, even more – an acute environmental challenge. In modern engines, less than half of the burnt fuel is used to perform useful work, and most of it negatively affects the biosphere.

Increased efficiency and resource, accompanied by the minimum allowable amount of harmful and polluting impurities in the exhaust gases, can translate ICE into the category of new generation engines. For specialists it is quite obvious that the cylinder-piston group basically solves this problem in the engine, in the interior of which physical, chemical and mechanical processes are performed. The effectiveness of these processes depends on the state of the kinematic system, its main elements “cylinder-piston rings-piston”.

It is known that the efficiency of an energy product depends on the various losses that accompany its work. The main losses in the engine operation are “gas leakage”, i.e. gas-dynamic losses, mechanical friction losses and thermal losses-thermodynamic losses. Approximately, even the magnitude of these losses, and the place of their origin is the GPG of the engine are known.

The cylinder piston group is the weakest link in the modern engine. With the failure of the CPG there is a necessity to perform engine overhauls. And the most vulnerable part of the CPG is the seal between the piston and the cylinder, which affects all processes occurring in the engine.

There are few specialists, scientists, practitioners who doubt that the modern internal combustion engine can be attributed to the latest achievement of science and technology of the 21st century. As researches have shown, the modern engine is considered perfect, there are no basis [3], [4]. The developers of ICE have not achieved the harmony between practice and theory. Uneconomically low efficiency of the engine, stopping at around 0.4, is evidence of a lack of serious theoretical developments in the design of the cylinder-piston group.

The problem of ICE effectiveness concerns the absolute majority of mankind. A huge number of different transport and special means using piston technology generated a large number of manufacturing firms and associations, small and medium businesses, which employ millions of jobs.

The quality of the equipment purchased and expensive is essential for determining demand and responsible supply.

Most often, the products are evaluated by the quality of its manufacture. For the energy product, the quality of the manufacture is also important, but the predominant characteristic must be its efficiency, based on the quality of design, construction and operation.

The main work in the kinematic scheme cylinder-piston ring-pistons produces a piston with very responsible structure elements-the piston rings. The cylinder, despite its significance, is a relatively static element of the engine design, the changes of which can be envisaged and reflected in its shape, size and technological processes. Therefore, the focus is on the simplest kinematic system of the ICE for the “piston-piston devices”.

Designing the new engine, or carrying out modernization of the engine in the course of scheduled or unscheduled repair, it is necessary to expect maximum efficiency which has to be significantly increased, that is the efficiency (E) of the engine has to be obviously more than 0,50. To increase the efficiency of the engine, it is necessary to exclude, or substantially reduce, all of the above losses.

The Internal combustion engine is not only the mechanics but also the physical processes that ensure its operation. The physical processes, in many ways, determine the mechanics of the engine, its shape and sizes, which then form the engine’s content, its technical and economic characteristics and its ecological performance.

The low efficiency of the engine is unacceptable-evidence of great losses and, as research has shown, most of them occur in the cylinder group.

This work is generally devoted to the research of gas-dynamic, hydraulic and thermodynamic processes impact occurring in the piston cylinder on main technical-economic and ecological showings of the engine.

Sealing Piston Devices

The internal combustion engine is subject to mechanical, gas-dynamic, hydrodynamic and thermodynamic influences that alter the shape and dimensions of its individual elements and parts that are in its natural and working conditions.

The developers who designing new engines, need to know what and how the physical processes affected to the transformation of the construction during the engine operation, which should be reflected in the developed projects.

The developers are not paying enough attention to these “physical processes”. We will consider in more detail what processes and in what part of the engine, cause changes. And what changes on which engine operation and its efficiency are depend.

The main source of changes in the engine is the cylinder-piston group, in which the main physical and chemical processes occur. They naturally affect to the operation of the engine. The cylinder-piston group determines not only the dimensions of the main engine elements, the connecting rod, the crankshaft and etc., but also the shape of the engine. Let’s try to figure this out.

The efficiency of any power device is estimated by the value of the efficiency, tending to unity, depending on the complex of various losses accompanying the operation of this device.

The specifics of internal combustion engines are that, in addition to the normal mechanical losses on the friction of the mobile elements of the kinematic system, there are gas dynamic losses, hydrodynamic losses (motor oil) and thermodynamic losses.

The thermodynamic changes in the engine during its operation have a significant effect on the efficiency of the cylinder-piston group. The thermodynamics changes the shape and dimensions of the cylinder, the piston, the piston rings, and it almost affects on all the processes that occur in the engine.

The engine losses may be objective, because of any physical process occurring within the construction, which is difficult for the developer and user to use during the operation of the product. But they can also be subjective because of the human factor that allows mistakes in the design, manufacture and operation of an energy device.

To significantly increase the efficiency of the engine, it was necessary to identify these errors and propose designs that exclude these losses, or reduce them to a negligible minimum. The example above shows that the opponent of the KAMAZ engine, the losses is much smaller and this naturally affects the efficiency of the engine, its shape and content.

The above losses, in general, should be attributed to the cylinder-piston engine group, which is rightly considered the “heart” of the motor that determines the technical and economic characteristics and ecological indicators of the engine. Low efficiency of the modern engine, this is, first of all, evidence of imperfection of the CPG engine and the errors committed during its design.

§1. Influence of the gas dynamics on the operation of a piston sealing ring

From the losses considered, it is necessary to highlight, as priority, gas-dynamic losses that affect the main working processes occurring in the combustion chamber and in the engine cylinder, as a result, on the efficiency of the engine.

The researches have shown that when analysis of various losses characteristic of the internal combustion engine and affecting on the value of its efficiency, the main task was to determine the location of each of them identify the priorities and influence on other groups of losses. Two groups of losses – mechanical and gas dynamic apply for the first post.

Let’s start with the dynamics. The domestic scientists and specialists mechanics, belong indulgently to gas dynamics as to the factor exerting serious impact on work of the ICE. In the best case, the gas dynamics for them is “leakage of the working gas”, determined for a single piston ring [5].

An analysis of the accuracy and value of the gaps in domestic engines shows that the theoretical calculations of the German scientist in determining the value of “leakage of working gas” have not found wide application in our country. – In the following, we consider some constructions, where the role of “leaks” is reduced to an insignificant minimum.

Turn to the materials in the domestic textbooks. “When the ring is compressed and inserted into the cylinder, it takes a cylindrical shape and exerts a pressure on the cylinder walls equal to 0,05 … 0,3 MPa (0,5 … 3 kg / cm2) and more. During operation, the pressure increases of the ring on the walls, since gases penetrating through the gaps between the ring and the piston press the ring against the wall of the cylinder”[6].

About the same, in 10 years. “The sealing is carried out by pressing the ring against the cylinder wall by the elasticity of the ring and the pressure of the gases. At the moment of flare when the piston is in upper dead center (UDC), the pressure in the groove of the 1st ring is close to the pressure Pz in the cylinder, and in the groove of the 2nd ring it is only 50% of this value. Pressure P3 behind the last ring is much smaller; it is commensurate with the pressure in the crankcase of the engine. In view of the considerable pressure of the rings on the cylinder walls, the majority of the work of friction in the engine (up to 50%, and sometimes up to 60%) falls on the rings, so it is impossible to press the rings with excessive force”[7].

The conclusions drawn by scientists on the one hand are quite obvious, and on the other hand inferior, are of a general nature, having little effect on the process of designing the piston rings. There is no answer to the main question: how, and with what efforts does the pressure of working gases in the cylinder act on the sealing piston ring?

The process of constantly changing pressure of intake air into a cylinder, then mixed together with the fuel in the combustion chamber and transfused into working gases, should be considered as a gas dynamic process.

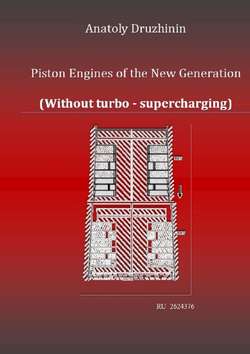

In 2004 for the first time the author published the gas-dynamic scheme of operation of the compression ring of the KAMAZ engine on the basis of an analysis of the established attitude of scientists and specialists of mechanics to gas dynamics [1]. This is how the design and position of the compression ring look without any slopes of the upper end face and chamfers along the inner diameter (Figure 1).

It was necessary to remember and use the known physical law, in the appendix to the given case it can sound as follows:

On the free surfaces of the piston ring (upper end and inside vertical surface) located in the closed space limited to a cylinder wall, a bottom of a piston groove and its upper and lower shelves which is under pressure of working gases, there are forces proportional to the areas of these surfaces

Figure. 1. The gas dynamic scheme of the operation of the compression ring of the KAMAZ engine: 1-A CYLINDER 2-A PISTON; 3-A PISTON RING

Breaking through the gap between the piston 2 and the cylinder 1 into the upper piston groove, the working pressure presses the piston ring 3 to the lower shelve of the piston groove with the gas-dynamic force F0, and to the cylinder wall by the radial force Frad and the force of intrinsic elasticity F seal. The calculation of these forces was provided in the author’s previous publications.

The most interesting can be seen in this calculation for one of the most popular domestic engines of VAZ-2190, with the following parameters: the maximum pressure of the working gases in the cylinder when the piston is at top dead center, is about Pwork = 80 kg / cm2. The dimensions are in centimetres for convenience of calculations. Diameter of the cylinder is 82 mm = 8.2 cm; the outer radius r1 is 41 mm = 4.1 cm; the inner radius is r2—38 mm = 3.8 cm; the radial thickness of the ring t = 3.0 mm = 0.3 cm; the height of the upper compression ring h = 1.5 mm = 0.15 cm.

The area of the upper butt is defined by the formula:

S1 = π (r12-r22) = 3.14 (4.12—3.82) = 3.14 (16.81—14.44) = 7.44 cm2.

The area of the inner vertical surface is defined by the formula: S2 = 2 πr2h = 6.28 × 3.8 × 0.15 = 3.58 cm2.

Multiplying the pressure of the working gases by the area values, we get:

Fo = Pwork × S1 = 80 × 7.44 = 595.2 kgf (5.95 kN);

Frad = Pwork × S2 = 80 × 3.58 = 286.4 kgf (2.86 kN).

The conclusion is obvious from the comparison of these two gas-dynamic forces acting on the movable piston ring. Twice the superior axial force reliably pressed the piston ring to the lower flange of the piston groove, depriving the radial force of the working surface of the piston ring from being pressed against the wall of the cylinder.

That is very important to note here. This pattern is observed in all cases where there is an excessive pressure on the piston. About this and not only, we will consider on the different steps of the engine motoring run. But now, running ahead, we can safely predict:

The gas dynamic scheme fundamentally changed the strategy and tactics, the theory and practice of designing internal combustion engines and piston compressors. It optimizes the size, shape and content of the engine and compressor and is reflected in the increase in the efficiency of both with its correct application in calculations.

All justifications are given in the author’s work and in this manual. The information were published and patented, brought to the attention of scientists and specialists of the motors. However, producers continue to “produce” super modern cars equipped with the engines with such significant defects. Let’s try again, to spell out in more detail the problem of increasing the efficiency of the internal combustion engines, which is not so difficult to understand, but very important for specialists.